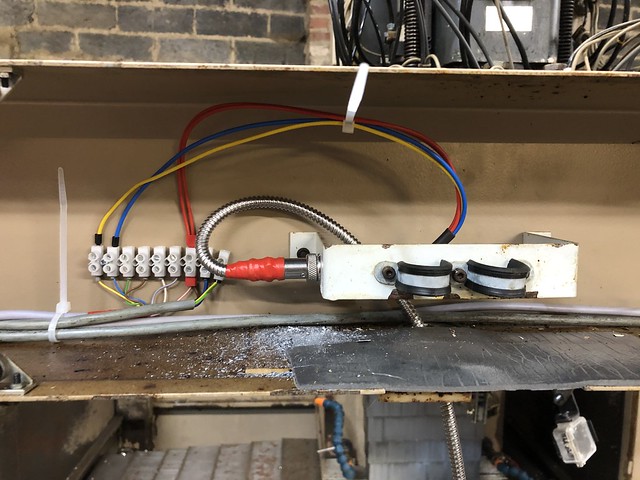

Es waren ja noch genug IO’s frei und um einem das Einrichten der Werkzeuge zu erleichtern habe ich mir einen einfachen Werkzeuglängensensor beschafft und in Igor verbaut. Das ist die erste Maßnahme, die über den Retrofit hinaus geht. Daher mussten hier erst mal neue Leitungen gezogen werden und ich habe die 7i77 in der Steuerkonsole dafür ausgesucht um die Wege kurz zu halten:

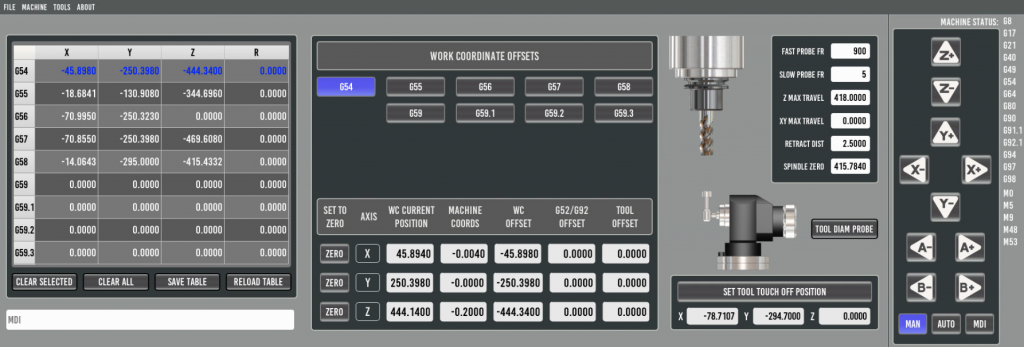

Jetzt musste noch die Software vorbereitet werden und der Ort hinterlegte werden. Das macht man im Offsets Tab, hier hinterlegt man auch ie Wege und Geschwindigkeiten für das Antasten

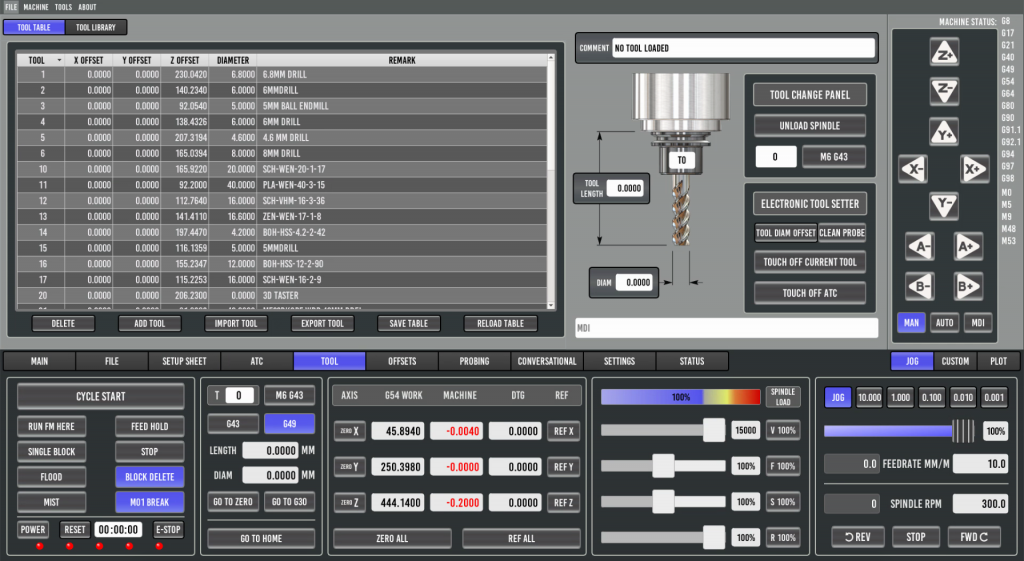

Die Steuerung erfolgt über den Tool Tab, auch hier habe ich mir wieder ein paar Sachen angepasst. Und jetzt kommt auch der Zeitpunkt wo ich auf mein Werkzeugwechsel-Script eingehen werde. Nicht alle meine Werkzeughalter sind für den Wechsler geeignet, daher unterscheide ich in allen Skripten zwischen Werkzeugen im Wechsler und welchen die Manuell gewechselt werden müssen. Doch später dazu mehr.

Zunächst gehen wir hier das Toolchange Panel durch:

Unload Spindle - MDI Button - M61 Q0 G49 #5210 = 0M6 G43 - subcall Button - m6_tool_call_tool_page.ngc

(author: Chris P)

(version: 0.1)

(date: 02/8/20)

(m6 tool call with g43 offset applied)

o<M6_tool_call_tool_page> sub

#<tool_number_entry_tool_page> = #1

T#<tool_number_entry_tool_page> M6

G43 H#<tool_number_entry_tool_page>

o<tool_number_entry_tool_page> endsub

M2 (end program)M6 - MDI Command remapped to - toolchang2.ngc

o<toolchange2> sub

(M108 P#<_current_tool> Q#<_selected_tool> )

;assign the tool numbers held in parameters to the pocket numbers

#1 = #5190

#2 = #5191

#3 = #5192

#4 = #5193

#5 = #5194

#6 = #5195

#7 = #5196

#8 = #5197

#9 = #5198

#10 = #5199

#11 = #5200

#12 = #5201

;assign the variables passed by M6 to some parameters

#100 = #<_selected_tool>

#110 = #<_current_tool>

(#120 = #<selected_pocket>)

O10 if [#100 EQ #110] ; checks if tool in the spindle is same as requested

o<toolchange> endsub [1]

M2

O10 endif

#<next_pocket> = 0 ; assigns 0 to the next pocket for a later check if the tool is found in the basket

#<loaded_pocket> = 0 ; assigns 0 to the next pocket for a later check if the tool is found in the basket and loaded

#15 = 12 ;assign test parameter the number of pockets in the carousel

O100 do

O110 if [#[5189 + #15] EQ #100] ; checks all pockets to see if it contains tool number requested as the new tool

#<next_pocket> = #15 ; if tool is found in pocket, assigns the next pocket

O110 endif

O115 if [#[5189 + #15] EQ #110] ; checks if the pocket is loaded in spindle

#<loaded_pocket> = #15

O115 endif

#15= [#15 - 1]

O100 while [#15 GT 0]

;now we know which pocket the next tool is sitting in

;and we know inwhich pocket the current tool is

;we need to know if we need to put a tool away

;or if there is no tool in the spindle

O180 IF [#110 GT 0] ; checks if there is a valid tool in the spindle

O190 if [#<loaded_pocket> EQ 0] ;If there is a tool in the spindle, checks if it is an pocket

; Go for manual Tool removal

G53 G0 Z0 ;raise spindle

G53 G0 X0 Y0 ;move to door

M125 ; remove tool

O190 endif

O195 if [#<loaded_pocket> GT 0] ;If there is a tool in the spindle, checks if it is an pocket

; Go for atc Tool removal

G0 G53 Z0 ; raise spindle

M110 ; draw bar loose

M112 ; lower basket

M116 ; raise pockets

O195 endif

O180 ENDIF

O200 IF [#100 GT 0] ; selected tool is not tool0

O210 if [#<next_pocket> EQ 0] ;if new tool is not in a pocket

; Go for manual Tool load

M113 ; Raise basket

G53 G0 Z0 ; Raise spindle

G53 G0 X0 Y0 ; move to door

M110 ; draw bar loose

M126 ; manual tool load

O210 endif

O215 if [#<next_pocket> GT 0] ;If new tool is in a pocket

; Go for atc Tool Load

G0 G53 Z0 ; raise sindle

M110 ; draw bar loose

M112 ; Lower basket

M131 P#<next_pocket> ; load pocket

M114 ; air blast

S150 M3 ; rotate spindle

M113 ; raise basket

M115 ; stop air blast

M111 ; clamp tool

M5 ; stop spindle

O215 endif

O200 Else

;new tool is 0 raise basket and clamp drawbar

M113 ;raise basket

M111 ;clamp drawbar

O200 ENDIF

M61 Q#100

o<toolchang2> endsub [1]

M2#!/bin/bash

#Manueller Werkzeugwechel M126

set -- $(halcmd -s show pin iocontrol.0.tool-prep-number)

newnr=$4

toolline=$(grep "T$newnr " tool.tbl )

tool=$(cut -d ";" -f2 <<< $toolline)

temp=$(cut -d "Z" -f2 <<< $toolline)

Offset=${temp:1:3}

zenity --info --title="Werkzeugwechsel" --text "Werkzeug: T$newnr \n\n $tool \n\n Z-Offset: $Offset mm \n\n einsetzen"

echo "Werkzeug spannen"

~/linuxcnc/configs/IgorProbe/nc_files/M111

zenity --info --title="Werkzeugwechsel" --text "Werkzeug T$newnr gespannt?"

exit 0Jetzt zu den Funktionen auf dem Toolsetter Panel

Clean Probe - MDI Button - M134 P2

#!/bin/bash

#M134 Druckluft fuer Werkzeugmesser

P=$1

Q=$2

case=$P

if [ -z "$1" ]

then

case=3

fi

#

if [ $case = 0 ]; then

halcmd sets o-probe-clean false

#

elif [ $case = 1 ]; then

halcmd sets o-probe-clean true

else

set -- $(halcmd -s show sig o-probe-clean)

open=$2

if [ "$open" == "FALSE" ] ; then

halcmd sets o-probe-clean true

else

halcmd sets o-probe-clean false

fi

fi

exit 0Touch off current tool - subcall Button - tool_touch_off.ngc

o<tool_touch_off> sub

#<worktable> = #<_hal[i-table-is-2]>

#<fast_probe_fr> = #1 (set from probe screen fast probe feed rate)

#<slow_probe_fr> = #2 (set from probe screen slow probe feedrate)

#<z_max_travel> = #3 (max z distance the tool travels before erroring out if not contact is made)

#<xy_max_travel> = #4 (max xy distance the tool travels before erroring out if not contact is made)

#<retract_distance> = #6 (distance the tool retracts after making contact during fast feed mode)

#<spindle_zero_height> = #5 (G53 distance from home to spindle nose triggering point on touch plate)

#<tool_diameter_probe_mode> = #8 (activates the tool diameter probe subroutine section)

#<tool_diameter_offset_mode> = #9 (activates the tool diameter offset position for probe subroutine section)

#<tool_diameter> = #10 (current tool's diameter used for offseting probe position in x axis)

o<100> if [#<worktable> EQ 0]

(need to change table for probing)

G53 G0 Z0 ;raise spindle

G53 G0 X0 Y0 ;move to door

M123

o<100> endif

G92.1 (Cancel G92 offset)

(#<workspace_z> = #[5203 + [20 * #5220]])

#<workspace_z> = #5220

#<tool_touch_x_coords> = #5181

#<tool_touch_y_coords> = #5182

#<tool_touch_z_coords> = #5183

#<tool_radius_offset> = [#<tool_diameter> / 2]

#<offset_probing_position> = [#<tool_touch_y_coords> + #<tool_radius_offset>]

G59.3

o<110> if [#<tool_diameter_offset_mode> EQ 1]

#<tool_touch_y_coords> = #<offset_probing_position>

o<110> endif

o<115> if [2 EQ 2]

G49 (cancel tlo)

o<115> endif

G90 (set absolute coordinates)

M134 P1 (blow of probe)

G53 G0 Z0 (move to z0 home position)

G53 G0 X#<tool_touch_x_coords> Y#<tool_touch_y_coords>

G53 G0 Z#<tool_touch_z_coords>

G91

F #<fast_probe_fr>

G38.2 Z-[#<z_max_travel>] (fast tool probe)

#<z_fast_probe> = #5063 (save probe result of fast probe to parameters)

G0 Z[#<retract_distance>] (retract tool retract distance amount)

(Slow Probe Rule, if Slow Probe FR is set to 0, Slow Probe is Bypassed)

o<120> if [#<slow_probe_fr> GT 0]

(Initiate Slow Z- Probe)

G91

F[#<slow_probe_fr>] (set probe slow feedrate)

G38.2 Z-[#<retract_distance> * 1.5] (slow tool probe)

#<z_slow_probe> = #5063

(debug, Probed Pos: #5063 Z Pos: #<_z>)

G90

G0 Z[#<z_slow_probe> + #<retract_distance>]

o<120> endif

o<130> if [#5070 EQ 1] (verify probe event was succesful)

#<z_slow_probe> = #5063 (save slow probe result to parameters)

o<130> else

(MSG,Tool Length Offset Probe Failed)

o<130> endif

(Tool Diameter Probe Mode Section, User must define this section as needed)

o<140> if [#<tool_diameter_probe_mode> EQ 1]

(MSG, Tool Diameter Probing is Not Defined in Subroutine)

o<140> endif

G49

o<150> if [3 EQ 3]

G49

o<150> endif

G90 (set absolute coordinates)

M134 P0 (stop blow of probe)

G53 G0 Z0 (Send Spindle to home zero position)

(define new tool length offset parameters)

#<new_tool_length_offset> = [ABS[#<spindle_zero_height> + #5063]]

G10 L1 P #5400 Z [#<new_tool_length_offset>] (5400 = tool number)

o<160> if [#<workspace_z> EQ 1]

G54

o<160> else if [#<workspace_z> EQ 2]

G55

o<160> else if [#<workspace_z> EQ 3]

G56

o<160> else if [#<workspace_z> EQ 4]

G57

o<160> else if [#<workspace_z> EQ 5]

G58

o<160> else if [#<workspace_z> EQ 6]

G59

o<160> else if [#<workspace_z> EQ 7]

G59.1

o<160> else if [#<workspace_z> EQ 8]

G59.2

o<160> endif

T #5400 G43 H #5400 (enable tool length offset)

o<170> if [#<worktable> EQ 0]

(need to chante table after probing)

G53 G0 Z0 ;raise spindle

G53 G0 X0 Y0 ;move to door

M122

o<170> endif

o<tool_touch_off> endsub

M2 (end program)Touch off ATC - subcall Button - atctouchoff.ngc

o<atctouchoff> sub

(print, o<atctouchoff>)

(DEBUG, EVAL[vcp.getWidget{"dynatc"}.atc_message{"Touch off ATC"}])

T0 M6; empty spindle

#1 = 0

o130 while [#1 LT 12]

#1 = [#1+1]

#2 = #[5189+#1]

o140 if [#2 GT 0]

(DEBUG, EVAL[vcp.getWidget{"dynatc"}.atc_message{"Touch off Tool #2 "}])

M6 T#2

o<tool_touch_off> call

o140 endif

o130 endwhile

(DEBUG, EVAL[vcp.getWidget{"dynatc"}.atc_message{"Igor"}])

o<atctouchoff> endsub [1]

M2